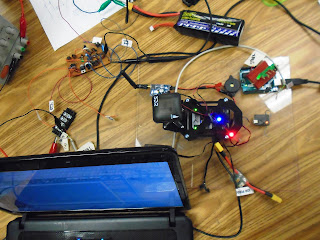

Logan Ranger Autonomous Vehicle Project 2016

Thank you to all involved!

2016 Logan HS PLTW Digital Electronics Class

District AV Video: https://www.youtube.com/watch?

AV Engineering Blog: Website: http://loganrangerav.blogspot.com/

AV Fabrication Video: https://www.youtube.com/watch?v=4eQo5_jsyT8

Logan High School Building Principal: Dr. Deb Markos

DESIGNED AND FABRICATED BY LA CROSSE LOGAN HIGH SCHOOL

DIGITAL ELECTRONICS CLASS:

THEO CARR , MICHAEL FELIX, KILLIAN HARNISH, DAVID KNUTSON, OWEN KOSIR ISAAC LIST, ZACH MAYER, DALLAS PATASKA, BEN PIERCE , JOE SCHMIDA

OSCAR SEXAUER, CLARE SIMPSON, JAMES SLADE, TYSON THOMAS

JOHN THORNTON-WEYRAUCH, KAO XIONG

INSTRUCTOR: STEVE JOHNSTON, LOGAN TECHNOLOGY & ENGINEERING DEPT.

CONTRIBUTORS (TECHNICAL EXPERTISE):

DAVE FOYE, ELECTRICAL ENGINEER

JUSTIN PITZ, LOGAN HS TECHNOLOGY & ENGINEERING INSTRUCTOR

JON BURMAN, WTC INSTRUCTOR

GREG SUTTON, TRANE MANUFACTURING ENGINEERING

MIKE ROACH, TRANE

JACOB SCHUMACHER, LOGAN HS TECHNOLOGY & ENGINEERING INSTRUCTOR

MOTION INDUSTRIES AND COURTNEY INDUSTRIAL BATTERY

TEACHER ASSISTANTS:

GRANT SIMMONS AND TRISTAN FINK

SPONSORED BY:

A GRANT FROM THE LACROSSE PUBLIC EDUCATION FOUNDATION

RANDY & JUDY EDDY FUND

TRANE / INGERSOLL RAND